Interesting explanation, but do not agree on that being the reason for all the small pieces. Im sure you can get the air bubbles out if there was only 4 pieces

I just let the pro's handle this part of the job for me so I could do other things that Im better at

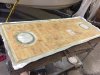

I don't disagree that larger pieces than 8" could work. I'm not a pro, but I will say that I had a heck of time getting the air bubbles out from a 2'x2' hatch I made. I ended up drilling a bunch of 1" holes in the wood, then filled the holes with thickened epoxy before putting a layer of glass on. On the other hand, I was rushing as I had to have everything ready to go the next morning for a 500-mile trip.

I suspect another reason for the 8" squares could be:

-- Easier for manufacturing. A 4'x8' sheet is easily divisible into 8" squares.

-- Different boats would have different sized hatches and floors (the boats with wood-cored floors ALSO were cored with 8" squares). Using 8" squares probably makes it easier to quickly adapt to different sized "areas". As the pieces get larger, you start to get into custom sizing (or more trimming), which takes longer. As you noticed in your hatch, it's not really all that important to have full coverage. The pieces can just be, well, "pieced" in - even somewhat haphazardly is fine. The strength of the hatch comes not from the actual core, but from the separation of the two layers of glass (hence the reason why that foamboard still works).

I'm envisioning that on the Grady plant floor, there are large bins of these 8" squares and the workers just fit them in the best they can - along with little chop saws right near by to quickly fit small pieces.