- Joined

- Jan 8, 2023

- Messages

- 27

- Reaction score

- 8

- Points

- 3

- Age

- 62

- Model

- Overnighter

Hi,

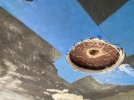

First time posting here. I have a 1999 208 adventure that unfortunately has been sitting for many years on a trailer in front of my house.

I live in new jersey and I think the weather might have done some damage to the transom, There are two cracks and I'm not sure if its just the gelcoat or something

more significant. They are on either side of the spalshwell (i think thats what it is called). I can jump on the 175 yamaha with no bend or give in the transom. Tried tapping

with a hammer and found a few small hollow sounding spots but none close to the motor. I have included some pictures. Just hoping to get some input from the more experienced on what it could be. Any suggestions on a good fiberglass repair in central/south jersey that I can trust would be helpful.

Thanks

First time posting here. I have a 1999 208 adventure that unfortunately has been sitting for many years on a trailer in front of my house.

I live in new jersey and I think the weather might have done some damage to the transom, There are two cracks and I'm not sure if its just the gelcoat or something

more significant. They are on either side of the spalshwell (i think thats what it is called). I can jump on the 175 yamaha with no bend or give in the transom. Tried tapping

with a hammer and found a few small hollow sounding spots but none close to the motor. I have included some pictures. Just hoping to get some input from the more experienced on what it could be. Any suggestions on a good fiberglass repair in central/south jersey that I can trust would be helpful.

Thanks