- Joined

- Dec 9, 2020

- Messages

- 57

- Reaction score

- 4

- Points

- 8

- Age

- 23

- Model

- Seafarer

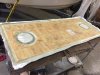

I have a 1990 Grady white 228g and at some point the previous owner put a single 80 gallon tank in it, the boat originally came with two tanks, on the floor in the middle of the back of the boat there is a huge hatch I think it was for the other fuel tank but nothing is in it now and the hatch that goes over it has a soft spot the whole center part of the hatch is a soft spot, and I was wondering if anybody else has had this problem or what to do with it.