- Joined

- Apr 13, 2021

- Messages

- 206

- Reaction score

- 70

- Points

- 28

- Age

- 67

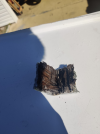

There are a lot of threads on GW rotted transoms. I have a 228 which is bracketed. I tested the core right after I bought the boat. It’s a 1988 and seems to have a dry transom. I drilled holes in the transom in a bunch of places, and the wood appeared to be dry.

My question is, are there any 228 owners who’ve experienced rot when your motor is mounted on the bracket and full transom?

My boat is in great shape with a new motor and I’m adding a hardtop in June. My hope is that the bracketed transoms will last longer and the boat will have some value when I go and sell it.

My question is, are there any 228 owners who’ve experienced rot when your motor is mounted on the bracket and full transom?

My boat is in great shape with a new motor and I’m adding a hardtop in June. My hope is that the bracketed transoms will last longer and the boat will have some value when I go and sell it.